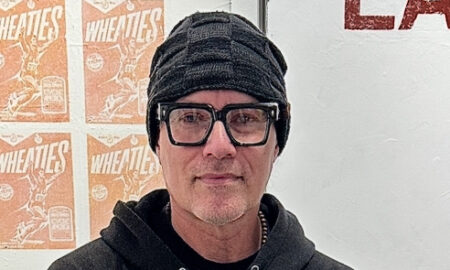

Today we’d like to introduce you to Jim Burton.

Thanks for sharing your story with us Jim. So, let’s start at the beginning and we can move on from there.

I began my maker journey when I switched my major in college from Chemistry to Fine Arts. I got my undergraduate degree in fine arts (BFA) in Valdosta, GA. In 2001, I moved to Denton after being accepted to the MFA program in Drawing and Painting at the University of North Texas. During my program, my work became multi-media and more sculptural, and I began becoming interested in traditional woodworking (cabinet making, joinery).

My artwork and my craft in joinery continued on a parallel path and began to merge in earnest in around 2010, when I purchased a home with a large studio and began to collect traditional hand tools (planes, saws, chisels). In addition to making my wood practice quite traditional using traditional hand tools and techniques more often than machinery, and relying on tried-and-true design cues… my art practice started including those traditional techniques in conceptual ways. I began fusing federal period furniture and furniture parts with marine foam and flocking and other mixed media. The furniture used in the sculpture provided me with a good counterpoint and punctuation to the highly theoretical themes in my artwork.

At the same time, the traditional aspects of my cabinet-making became more precise, and I began to learn more esoteric old-world joinery techniques. Learning these old techniques allows me to fuse traditional materials and joinery methods with a contemporary clean design that can easily fit in the modern household but will last far longer than mass-produced furniture.

Now, I have two separate practices that influence each other… one, a conceptual sculptural and painting practice that is informed by a traditional craft ethos, and a traditional furniture practice relying heavily on hand tools, but made malleable and free as it is informed by my artwork. I make small runs of special items… tables, shaker lap desks, traditional furniture as well as being able to take on interesting projects that require outside-the-box thinking and a large and flexible skillset. In a sense, I will consult with a client, offer them a traditionally constructed version of the modern furniture or built-in or feature that they are looking for. It’s quite specialized and my time-frame isn’t nearly as fast as a large production shop. However, I provide a product that utilized methods of construction that are proven to last for centuries, not decades. Also, a personal, unique touch adds to the end user’s experience, and the patina that these pieces acquire over the years and decades of use will only add to their value.

Great, so let’s dig a little deeper into the story – has it been an easy path overall and if not, what were the challenges you’ve had to overcome?

I believe that every experience that I have had does shape the craftsman I am today. Thus, I don’t view the experiences as good or bad. It is hard being a one-man operation, and there are a lot of long, sweaty days, especially when I stretch the limits of my home studio. The move to commission and custom work came quite serendipitously.

A challenge is educating the public and potential clients on just the lengths to which I go, why those methods are better, and why the cost for a custom piece is so high. In an age when an IKEA end table can be purchased for $10, it is difficult to express to someone why a similar design of the table made by me would cost $1000. And indeed, some people fail to see worth in that craftsmanship. I speak to those who are discriminating and understand the love and skill involved in the making of their special piece. These rare customers also understand that they are receiving an heirloom piece… not a temporary solution to store their people magazines.

I have to be realistic about the jobs that I take, and I turn down about 60-70% of commissions I am approached about. As this is not just a source of income for me, but real, palpable enrichment for me soul, I can afford to do that, and that very high bar of my choices show to those who matter and would prefer a custom and rarefied piece over convenience and thrift.

We’d love to hear more about your art.

My woodwork is grounded in tradition. I start with real, sustainably harvested hardwood (though I also sometimes use good softwoods like pine and cypress, when appropriate). I employ methods of working that wood that are centuries old and are technically sound. I am able to be far, far more precise by finishing all of the work with hand tools rather than machining with table saws or power planers or sanders. Though I am not a luddite and do use power tools when appropriate, the final piece is always, always touched with a plane, a saw, a chisel. Joinery, such as dovetails and mortise and tenon joints, are always cut by hand, as I am able to be more precise and flexible based on what the wood needs.

Mostly, I make small home furnishings… beds, chests, drawers, tables. I also make boxes of all shapes and sizes and usages, from valets to traditional lap desks to dry food storage to memorial urns. My shop is relatively small, so I am not able to produce large production runs, so all of my pieces are custom and designed specifically for each client. I rarely have any stock available for immediate purchase, as my work can take many months, depending on the complexity.

I believe I am set apart by my absolute love for the various woods properties. Sometimes, old-growth cherry is my favorite, as fruit woods are so tight-grained and beautiful. Sometimes, the heft and ruggedness of white oak is appropriate. Sometimes, the luminescence and depth of mahogany is necessary, or the flashy, shimmery impossibility of curly maple is what a piece calls for. Whatever the piece, whatever the wood, I never, ever use artificial colorings or stains, much preferring the wood’s natural beauty be on display. Planing a surface to finish is superior to sanding the surface to finish. Natural oil finishes or polished French surfaces allow the wood to be itself, not masquerade as something it’s not. I believe that my incessant study of the history of woodcraft and the love of technique and process is what makes my work desirable and collectible.

Is there a characteristic or quality that you feel is essential to success?

Sincerity. Genuineness. Adherence to a superior standard of craft and craftsmanship. A palpable love and respect and humility for both the wood and the countless craftsman whose discoveries I stand upon.

Contact Info:

- Phone: 940-222-1520

- Email: james.burton@unt.edu

- Instagram: https://www.instagram.com/burtonwoodworking/

Suggest a story: VoyageDallas is built on recommendations from the community; it’s how we uncover hidden gems, so if you or someone you know deserves recognition please let us know here.