Today we’d like to introduce you to Tiffiny Guerra.

Hi Tiffiny, thanks for joining us today. We’d love for you to start by introducing yourself.

What began as a simple moment between a mother and her daughter ultimately became the foundation of an entirely new industry.

In 2014, just before Thanksgiving, our family had Christmas lights installed on our roof for the very first time. My daughter was almost three years old, and when she looked up and saw the lights glowing against the night sky, her face lit up with pure wonder. That single moment changed everything.

That year, I went all out. We decorated the entire yard- lighted reindeer, snowmen, musical Christmas trees, twinkling presents. We spent hours setting everything up. My neck and back were sore, my body was exhausted, but none of that mattered. Watching my daughter’s joy made every ache worth it.

Every night, we had a ritual. We would walk outside together, turn on the lights, and sing along to the Christmas music playing in the yard. To a three-year-old, it wasn’t just decorations- it was magic.

Then one evening, right in the middle of singing Jingle Bells, it started to rain.

The music stopped.

The lights went out.

The yard went dark.

There were tears- hers, and maybe a few of mine too. All that time, money, and effort disappeared in seconds because of a little rain. I was frustrated, heartbroken, and determined. There had to be a better way.

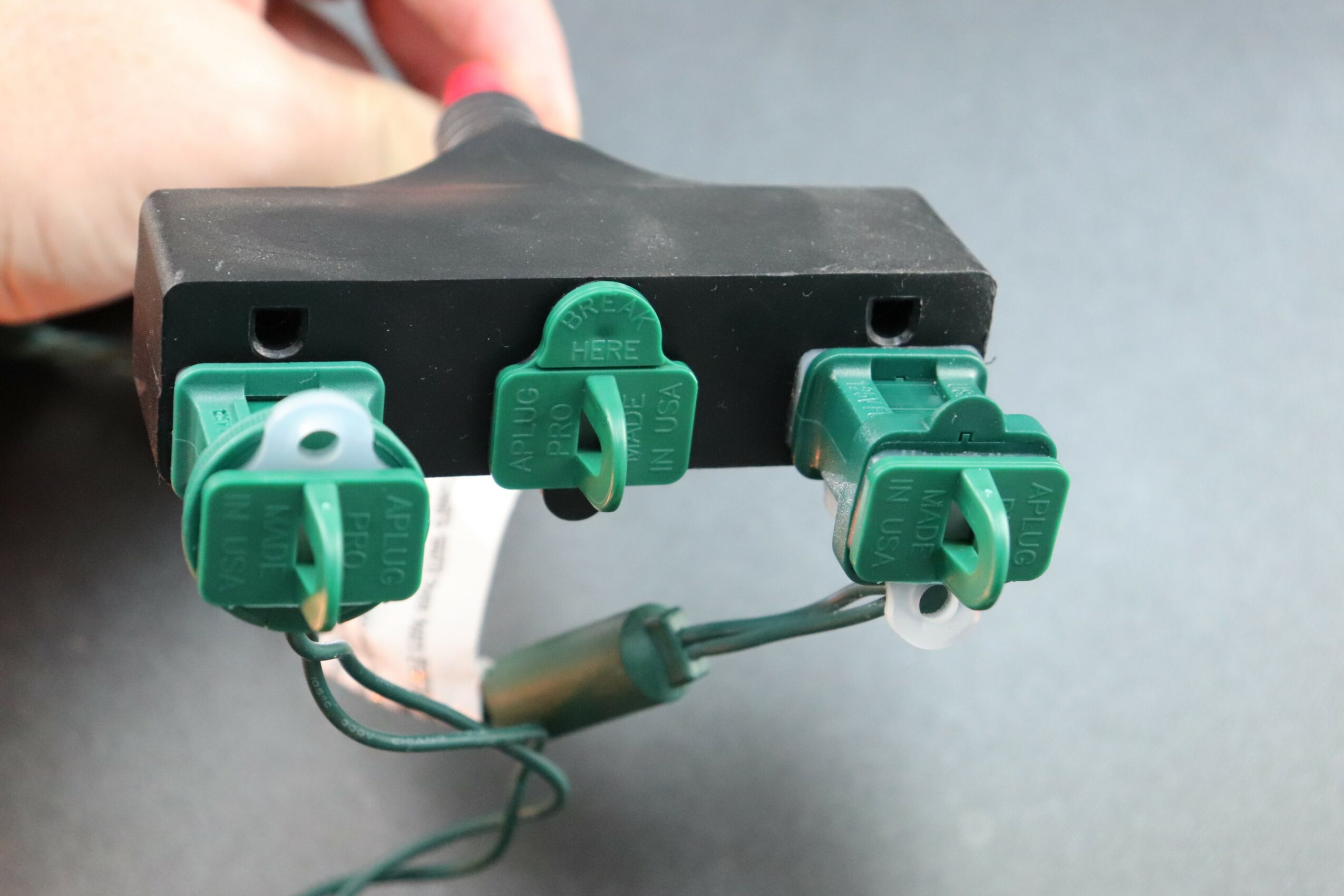

We tried everything. Plastic baggies. Electrical tape. Every DIY “fix” we could find. But water always does what water does- it finds a way in. The only commercial solutions available were bulky, expensive extension cord boxes that didn’t bend, didn’t work on trees, and weren’t practical for dozens of connections.

When I started talking to neighbors, I realized we weren’t alone. Every yard went dark when it rained. Everyone was resetting GFCIs. Everyone was frustrated. Everyone wanted a simple, affordable solution.

That’s when the idea hit: What if we could actually solve this?

What followed was more than a year of intense research and development. Hundreds of hours. Dozens of failures. Countless material tests. With the help of licensed electricians, engineers, and machine shop professionals, we experimented relentlessly until we finally cracked it- an impenetrable yet flexible weatherproof gasket that sealed connections properly.

By the next holiday season, we tested our product in real-world conditions. It rained. It poured. And for the first time…

The GFCIs didn’t trip. The lights stayed on.

Friends and neighbors wanted them immediately. Orders followed. Then more orders. And suddenly, what started as a solution for one little girl’s Christmas magic became a growing business.

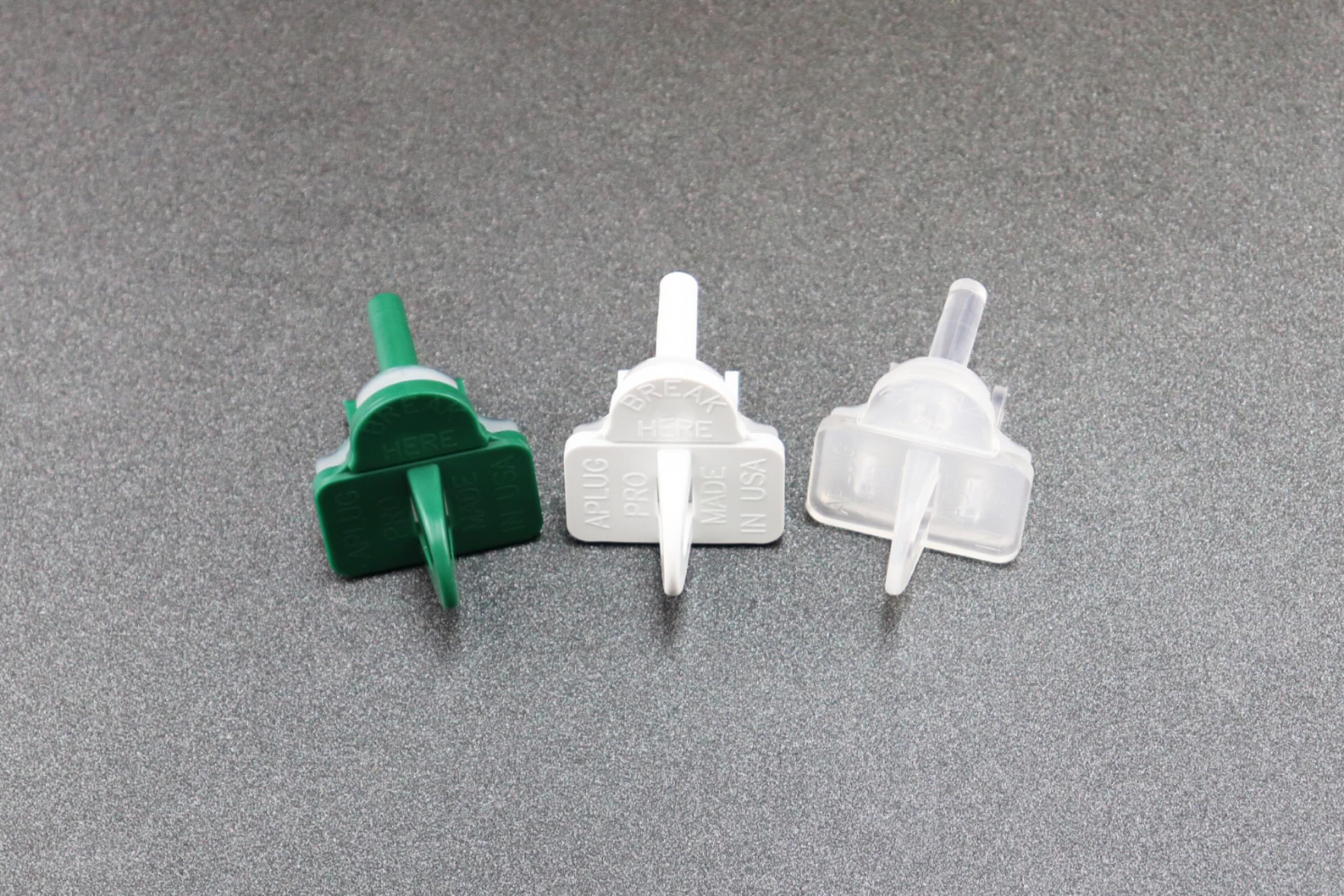

The early days weren’t easy. Manufacturing was slow and painstaking. We built our first machine ourselves-then realized it wouldn’t keep up with demand. Over time, we designed and built three additional specialized machines. We created hundreds of molds. Our plug cover design was revised and perfected four separate times- changing materials, refining the shape, improving performance, and even adding color.

Every gasket is still handmade and individually inspected before it leaves our door.

We built our website and Amazon store from scratch. We shipped hundreds of orders a day ourselves during peak seasons- often sacrificing holidays, including Thanksgivings, to keep customers taken care of. We grew by building real relationships, especially within the Christmas light installer community, connecting one conversation at a time.

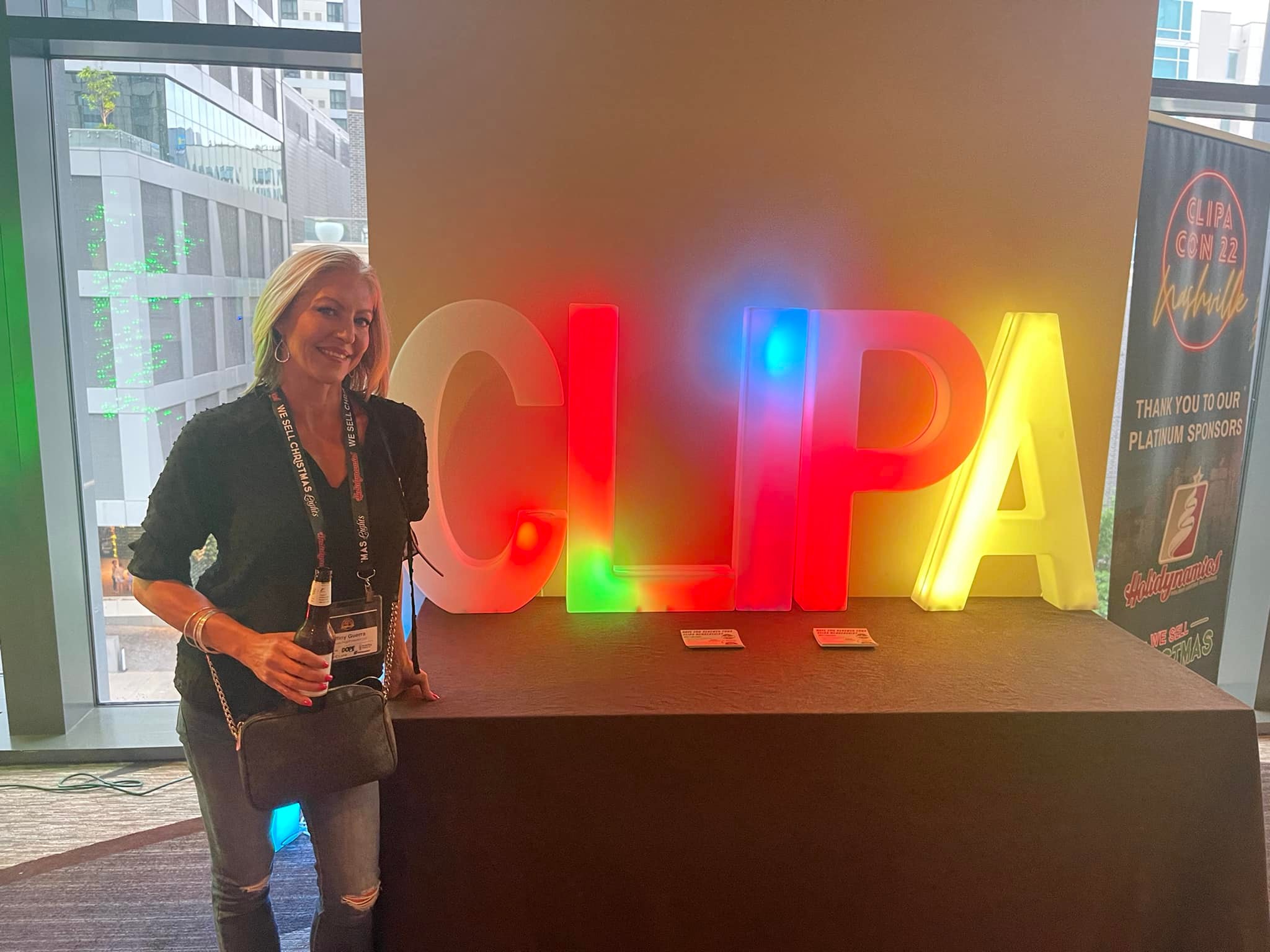

In 2022, we attended our first industry trade show. In 2023, during a major neck surgery that fused five vertebrae, friends and family stepped in to help keep production going. That same year, our business unexpectedly skyrocketed, forcing us into Amazon FBA during one of the most challenging personal seasons of my life.

Through growth, competition, copycats, and challenges-including an influx of low-quality overseas knockoffs-we have never lost sight of what matters most: our customers and our integrity. Our gaskets work for 99% of users, and when they don’t, we help people find the real solution. We stand behind our products fully.

Today, we are a family-owned company, run from my home so I can be present for my children. I’m a single mom. Family comes first-always. Our first employees were single moms and stay-at-home moms. We treat our customers like family because that’s how this company was built.

What started as a rainy night and a disappointed little girl has grown into a brand known as Your Power Guardian- protecting power, preventing frustration, and keeping the lights on when it matters most.

None of this would have been possible without our customers. Because of you, a simple solution turned into an industry. And because of one little girl’s smile, we’ll never stop innovating.

I’m sure it wasn’t obstacle-free, but would you say the journey has been fairly smooth so far?

Not at all. In many ways, the challenges are what shaped both me and this company.

I built this from scratch with no formal training, no blueprint, and no roadmap. There was no instruction manual for creating a product that did not exist or for turning a simple idea into an entirely new category. Everything I learned came through trial, error, persistence, and a willingness to keep going when things felt overwhelming.

One of the most difficult seasons came when I received devastating medical news. I was told I was one healthy sneeze away from becoming quadriplegic. An infection from a prior disc replacement surgery had weakened the bones in my neck to the point that they began to collapse, leaving me in constant, overwhelming pain. I had to undergo a life-altering surgery followed by physical therapy, all while trying to keep the business running.

At that time, I did not have the incredible team I have today. I relied heavily on friends and family to help manufacture and ship hundreds of orders each day so our customers would not be affected. Without their support, the business would not have survived. I was also incredibly fortunate that my father owns a machine shop. He machined the hundreds of molds we needed and helped build the machines that allowed us to keep up with demand during a time when I physically could not do much myself.

In the middle of all of this, we faced a legal threat because our original company name was too close to another business. To avoid a lawsuit, we made the difficult decision to rebrand from APP to APlugPro. That meant redesigning everything from our logo and website to our packaging, and walking away from tens of thousands of dollars of work so we could move forward without distraction.

Then, right before our most recent busy season, I discovered that more than a dozen overseas manufacturers had copied our product design and were attempting to use our intellectual property to sell competing products online. To make matters worse, they had hacked our website to study our pricing structure. After everything we had already endured, it was incredibly discouraging, but we kept moving forward.

There were also significant technical and manufacturing challenges. We use two types of molds in our production. Our gasket molds are used repeatedly to pour each batch of gasket material. Because the material is extremely sticky before it cures, the molds must be power washed to remove uncured material. Over time, we redesigned those molds to be lighter, smoother, and more efficient, improving both output and consistency.

Our plug cover mold presented its own set of challenges. That mold is used hundreds of thousands of times and constantly cycles through heating and cooling. Early on, it broke unexpectedly. Because production could not stop, we reverted to an earlier version of the mold that did not include a grip hole and only had a smooth pull tab. To keep orders moving and customers served, I hired two moms who hand drilled every single grip hole, one by one, so we could continue fulfilling orders without interruption.

We tested multiple manufacturing methods before settling on the process we use today. Even now, production remains hands on and labor intensive. We have gone through hundreds of molds and four major design evolutions, always focused on improving the product.

Along the way, there were long days, missed family holidays, health setbacks, and learning e-commerce as we went. As the business grew, increased competition and copycat products followed, which only strengthened our commitment to quality, education, and standing behind our customers.

None of it was easy, but every challenge forced me to adapt, learn, and keep going. What began as a simple moment between a mother and her daughter ultimately became the foundation of an entirely new industry. The road was not smooth, but it was worth it.

Alright, so let’s switch gears a bit and talk business. What should we know about your work?

Before starting APlugPro, I spent 15 years as an esthetician, building my own client base and managing my own schedule. Eventually, I became a stay-at-home mom, and my priorities shifted completely to my children – the greatest accomplishment of my life.

Becoming the owner of APlugPro was a natural next step. I had to learn everything from scratch – product development, manufacturing, running a business, social media marketing, and e-commerce – all on my own. I specialize in creating high-quality, reliable weatherproof solutions for holiday lighting and electrical connections, and I’m known for my commitment to craftsmanship, excellent customer service, attention to detail, and hands-on approach.

What sets me apart is that I’ve built this company from the ground up without formal training, all while raising my children and making sure every product meets the highest standards. I’m proud that APlugPro not only provides a practical solution to a widespread problem, but is also family-centered, supports other moms in the workforce, and keeps the lights – and smiles – on for thousands of customers.

Can you talk to us a bit about the role of luck?

Luck has definitely played a role – but mostly, it’s been a mix of good timing, unexpected challenges, and making the most of every situation. For example, starting APlugPro just before a surge of interest in holiday lighting and finding an untapped need for weatherproof gaskets was lucky timing. On the flip side, I’ve faced bad luck too – like health setbacks, mold breakages, and distributors making decisions that could have derailed the business.

In every case, luck alone wasn’t enough. What really mattered was how I responded – pivoting, problem-solving, and relying on friends, family, and a dedicated team to keep the company moving forward. In that way, luck gave me opportunities, but perseverance and creativity made them count.

Pricing:

- Weatherproof Gaskets: $4.97 – $50.97 per pack, depending on size and quantity

- Plug Cover Kits: $5.97 – $44.97 per kit, depending on quantity

- All products are handmade, carefully inspected, and built to last. made in USA

- Available through our website and Amazon FBA, with volume discounts for installers, decorators, and commercial customers

- Designed to protect electrical connections from rain and moisture, preventing tripped GFCIs and keeping lights and decorations on

Contact Info:

- Website: https://www.aplugpro.com

- Instagram: https://www.instagram.com/aplugpro/

- Facebook: https://www.facebook.com/aplugpro/

- Twitter: https://x.com/aplugpro

- Youtube: https://www.youtube.com/@APlugPro

Image Credits:

APlugPro

Photographers paid: Zach Browne and Paul Lara