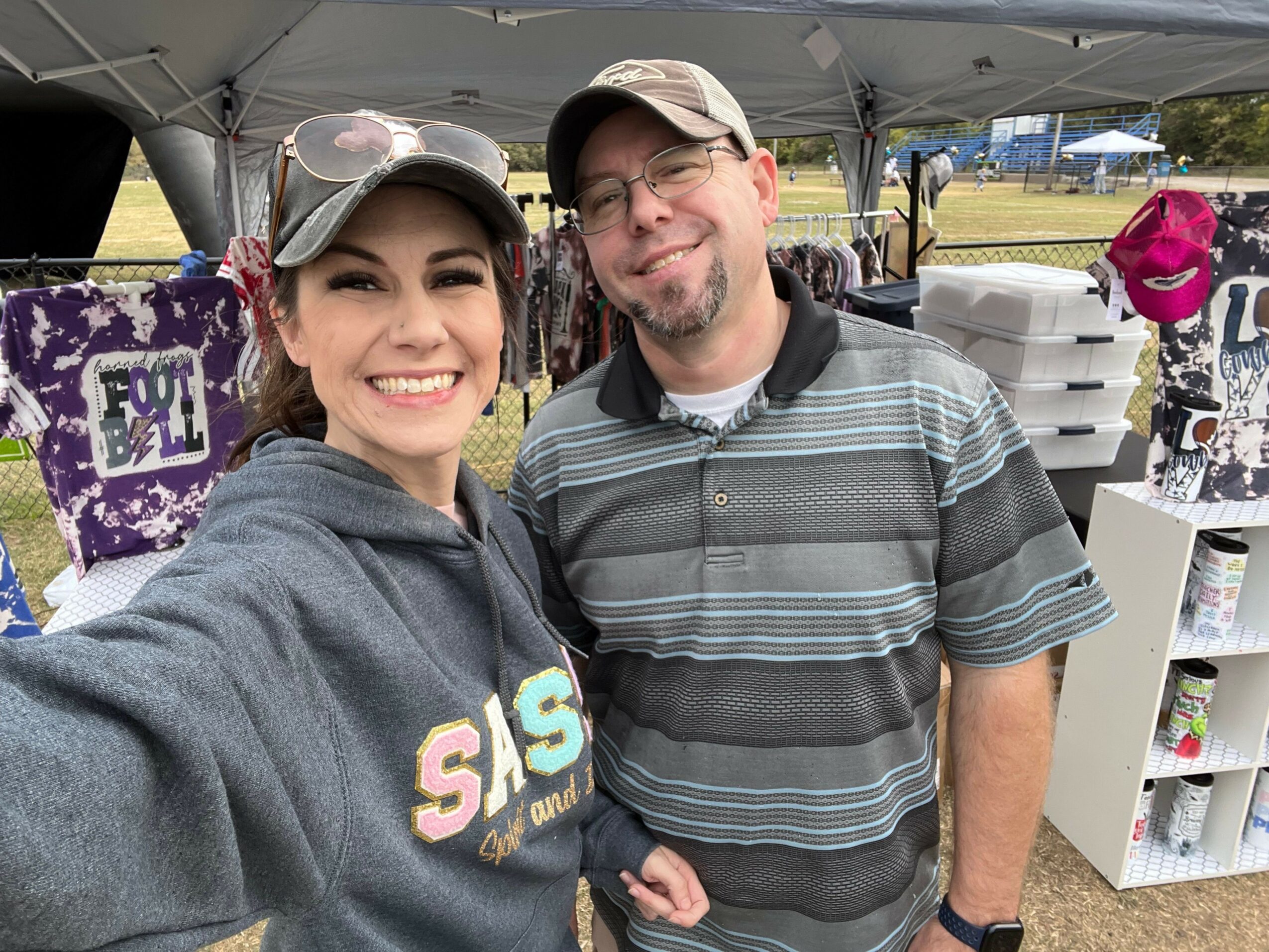

Today we’d like to introduce you to Alyssa Hultquist

Hi Alyssa, we’re thrilled to have a chance to learn your story today. So, before we get into specifics, maybe you can briefly walk us through how you got to where you are today?

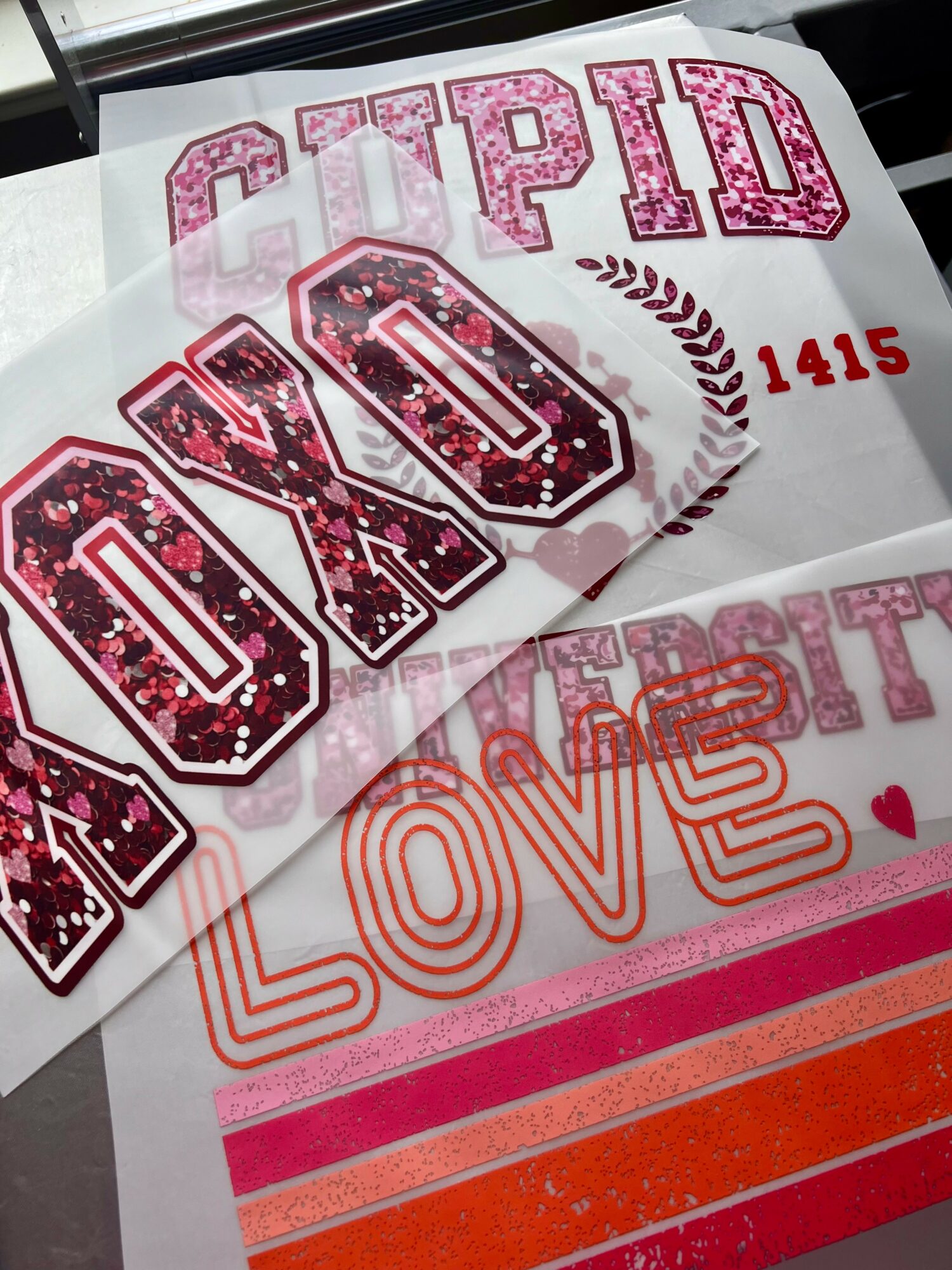

Straight out of highschool, I landed a CAD job with a local engineering company. I love computer and graphics design, and learned a lot in the 8 years I got to work at Halff Associates. However, the opportunity came along for me to leave the company and be a full time mom at home. Problem was, I love to work, and so I set a goal to make income from home. I tried various things. I sold life insurance, jewelry, drop shipped on eBay… we eventually started powder coating the YETI tumblers and reselling them in color! This was way before they made colored ones. From there, clients wanted customization, so I started dabbling with vinyl and making designs again! Except this time, it wasn’t storm drains or roadways I was designing haha! I got to learn a whole new world of graphics and design. And I enjoyed it SO much more. We customized tumblers for 7 years and the proceeds helped pay for my mother’s alternative cancer treatment. She was stage IV metastatic breast cancer and chemo was not an option. That little business paid over $60k in medical bills at the Kotsanis Institute in Grapevine. I give them the credit for helping her live a quality life for almost 5 years after her rediagnosis. But then, the customized tumbler world got really saturated with makers, and it became difficult to compete when epoxy glitter tumblers became popular. We definitely preferred powder coating and etching designs way more, but they were not what the people wanted anymore. So we closed those doors and I tried to just be a mom at home. Again, problem was I liked working haha! I started making homecoming mums when my oldest daughter started high school and I ended up making SO MANY for the local kids and schools, Boswell HS, my almamater LD Bell, all the way down to Burleson… I had mums all over, but so was the glitter, and my husband just supportively rolled his eyes at me and my mess of ribbons and trinkets. I found school spirit was my happy place. I absolutely fell in love with it. Dancing for the Raiderettes at LD Bell throughout all 3 years of highschool “saved” me and is honestly why I love School Spirit so much. I had always said I would NEVER make shirts because I absolutely HATED vinyl! Not only was it horrible to mess with and a pain to weed, but the longevity wasn’t there, and I like to only put out the “best” .. I do not like complaints. So when sublimation became popular, I learned how to bleach shirts and that’s where Sassy Spirit and Design was born in 2021! I bleached over 20 shirts a day in my backyard!!! Not always because I had a sale, but because we were headed into the Fall Vendor season for all the school craft shows!!! I knew if I could get out there and market my awesome clothes, I knew I could sell them at the shows, and hopefully build a following!! Which I absolutely did! I think I did 8 shows that year, LD bell, Boswell, Saginaw HS, Eaton HS, Saginaw Train and Grain, Saginaw Christmas Market, Azle, SYA Football and some others!! My husband would load up his truck with all my goodies, he would drive with me, help me set up, and then leave me to do my thing! Sometimes my oldest daughter would want to come work with me and it really became a BIG family thing to come see Mom, or be with Mom as she worked the Sassy booth. Even my awesome Mother in Law would come support me and work with me some times. It was a lot of work to do shows, but I loved meeting people and talking about my craft!! I especially loved going back to my old high school and being able to help support their fundraisers!! Especially my fellow Raiderettes. After a couple of years doing the shows, I certainly kept busy and had a great following. I worked Sassy full time bleaching and tie dying, but it was about to kill me if I’m honest. That’s so very laborious. That’s when Direct-to-Film came into America. It was being talked about in the Facebook groups and I searched high and low for someone local to me to print DTF transfers. There wasn’t anyone!! At that time, DTF was maybe 2 years old. But it was the first new thing to hit the shirt industry in 27 years! DTG (direct to garmet) was the last thing new process for shirts in 1996. I saw DTF was going to be a game changer for the shirt makers due to its versatility and easy reproduction. So many moms make shirts for their kids sports teams or birthday parties, and I’m going to circle back to how awful vinyl is!! And how time consuming!!! Anyways, that said, I became very intrigued and decided I wanted to learn how to print the DTF transfers. The giant commercial machines reminded me of my old plotter room at Halff Associates and when we would print out the giant schematics – which I loved those big rolls of roadway!! I saw this as a way for me to get my brain engineering again. I got a small converted L1800 printer and that was the beginning of my love for printing. I can’t explain how many sleepless nights I’d be on the phone with my Chinese engineer trying to understand and tinker on that printer. There was always a problem. To start, a sensor had fallen off during shipping, so I had to dismantle it completely to fix it. However, I was really enjoying the tinkering. It irritated me, but the sense of satisfaction and accomplishment when it would work again made me feel like super woman! I was determined to learn this industry hardly anyone in the states knew how to do. I saw the demand for it and there was no one around me who did it. That Christmas I spent 12 hours a day, every day, printing on that machine that took an entire hour to print 1 design haha! But I started building a following for DTF transfers and I learned how to source materials that would provide a soft feel once applied. Not all materials are good, and so many transfers feel like hard plastic. I was determined I wouldn’t have that kind of feedback. I wanted to be the best. We saw how demand was growing and we invested in a big commercial printer. I had done a lot of research and I found a network of other printers in America spread out all over the country. We would discuss inks, film, softwares, printheads and maintenance etc. Together we all grew!! I started running the commercial printer in my garage in January 2022. I hired a team to build a wall in my garage, update all the electrical I would need, install the mini split to keep it cool and maintain the perfect work environment for the best possible printing. It was a big investment and leap of faith. I struggled BIG time as the growing pains and learning challenges were very steep. So many times I wanted to give up and was so worried I had finally met my match, but with the support of my amazing husband, he helped me replace headboards and motherboards, and together we finally found a good groove. I was finally able to run days and weeks without issues. DTF printing can be unpredictable and moody. Big Bertha was the name we gave our 1st commercial printer and she gave me some challenges for sure!! However, she’s a work horse. For the next couple years she ran 10-14 hours a day printing out orders. It became very exhausting. I couldn’t keep up with demand and my family was suffering. I didn’t get to see my kids anymore. If I did, they were coming to hang out in the garage with me. I knew I had to make a change because that’s not why I wanted to work from home. I needed to be off work when they returned from school. So we started looking around at commercial spaces so I could get a 2nd faster printer. We had almost signed a contract on a place in Haslet, but I just couldn’t do it. It was so much money each month for a “shop”. I didn’t need or want a “storefront”. We decided it would be wiser for us to move to a new house where we could build what we needed and invest into our own home and land. We searched all over the Fort Worth area so my husband could still have an easy drive to work. We found the perfect spot up in Rhome, just 25 minutes north of our old house. The house was ready to move in, had a 3 car garage and many of the neighbors already had my dream shop built in their backyards!! This was the place. We listed our house and moved in 30 days. We were told we were crazy and we moved too quickly. Truth is, we just knew what we wanted and we don’t tend to overthink. We think and we act. We’ve been in our new spot since 7/31/24 and our business has doubled. We still offer a Saginaw pickup spot too! I had reached out to the owners of Saginaw Nutrition asking if they would be open to housing my pick box inside their store to help keep my locals happy. And I couldn’t believe it when she said yes! We had never met. I just knew Jen had the same love for team sports and the local youth that I do! So far, this partnership has worked out perfectly! Many of my clients grab a healthy treat when they go to pickup their prints! I drive to fill the Saginaw box 3 times a week, and while there’s been growing pains, they seem to have worked themselves out rather quickly! I use a Bluetooth lock and generate codes for clients to pickup. They expire after 1 use and this just keeps good records of who is accessing the pickup bin. I did have a thief one time in the very beginning before I used the lock system. The locks have been in use for almost 2 years now, and my regulars have their own permanent codes. Since our move, my new 4-head commercial printer (Blanche is her name) has been rocking and rolling every week day and she gets my work queue done 5x faster!! I now can offer FREE same day rush for all orders placed before 1pm, and I’m done with work by the time the kids get home from school! I’m back to cooking dinners and enjoying the evenings with my family!! It’s amazing to look back and see the growth. I know it was hard. I often told my kids that Mommy was working hard on something BIG and our sacrifice would be worth it one day, and to just believe in me and trust me. I’m so thankful I’ve been able to persevere and build Sassy to what it is today. If I hadn’t found a way to contribute financially from home, I was going to have to go out and get a “real job” again and that was the ultimate motivator. I love working for myself and working from home. I love marketing and meeting new people. I love an industry that’s constantly evolving. And I REALLY love working with the local schools. We are an approved vendor with Eagle Mountain-Saginaw ISD and I get to help make spirit wear for so many of the schools. My BIG account is Pure Gold Dance Team at Boswell HS. I love making all their stuff and helping their booster make money!! It’s so fun to be involved at this level and to help so many small businesses grow as well. We get told often how much our quality transfers and fast turn around time has “saved” their dying business and they are now growing again. Which in this economy?? That’s incredible!! So many moms have ditched the vinyl and use Sassy transfers now. I’ve found the perfect combination (for now) to provide the softest, thinnest and most vibrant prints on the market! The longevity certainly outlasts vinyl and dare I say screen printing too?! I’m very proud of what we’ve been able to build and from where it all started. This is very much a family owned business. Every single one of my kids helps me and I love teaching them to love what you do!

Alright, so let’s dig a little deeper into the story – has it been an easy path overall and if not, what were the challenges you’ve had to overcome?

Absolutely not. Technicalities of a printer are endless. I’ve fried so many parts and damaged so many printheads. Thousands of dollars wasted on replacing things I messed up in the process of learning. I also learned not to hire people you love and value. Unfortunately money and stress of working can damage even the strongest relationships. My closest a friend of over 16 years was in need of a job and I was in need of help! We had a “contingency plan” to preserve our relationship knowing of the long standing advice to not work with family/friends. Unfortunately, that plan failed and our amazing friendship is no more. I’d say my only regret in this life is having hired my best friend.

Alright, so let’s switch gears a bit and talk business. What should we know?

I covered a lot in the section that said to provide a “brief” description haha! We are known for being the best. Product and service. I want my clients to know we will take care of them and help them grow. We source only the best raw materials to make sure our clients receive only the best transfers. We use our transfers too, so we want our finished products to also feel nice and be well liked! Longevity is a big deal to me. I know our product is going to last!

Can you talk to us a bit about happiness and what makes you happy?

I’m happy when I feel valued and successful. At work, at home, in all relationships. I enjoy knowing I’m contributing and helping make a difference in the lives of others. I’m happy I get to spend time with my family and be at every school event! I’m happy I’ve been able to persevere and not give up when I wanted to most. I know my mom would be so very proud of the life we’ve been able to build because of our business.

Pricing:

- Full Sized Single Prints $5

- 24” Gang Sheets $4/sqft

- Bulk Order Tees start at $12 and vary in cost based on design and desired brand

- Custom Designs start at $5

Contact Info:

- Website: https://sassyspiritstx.com

- Instagram: https://Instagram.com/sassyspiritstx

- Facebook: https://Facebook.com/sassyspiritstx

- Youtube: https://youtube.com/@sassyspiritstx

- Other: https://TikTok.com/sassyspiritstx