Today we’d like to introduce you to Dale Norwood.

Hi Dale, so excited to have you on the platform. So before we get into questions about your work-life, maybe you can bring our readers up to speed on your story and how you got to where you are today?

I guess you could say my story began in 1980. That was then when I accepted a position as a (NDT) Non-Destructive Testing Technician at Ultrasonic Research & Testing Laboratories, Inc. in Dallas, Texas. Also known as URT.

At the time I had obtained about 3 years experience as an NDT Inspector working for a FT. Worth testing lab. It was a very exciting time for me. Ultrasonic Research had the reputation as the premier NDT lab in the United States with most of their work focusing on the aerospace industry, both commercial and military.

For those of you not familiar with the NDT profession, it is an industry that plays a vital role in product safety. NDT is used to inspect critical components of commercial and military aircraft, ships, subs, weaponry, rockets etc. as well as extensive use in the Oil & Gas Industry. Most people have no idea the NDT field exist. To give you a brief overview of what NDT is, it consist of various inspection methods. These inspection methods check the product for cracks or a variety of other defects that might be present. If these defects go undetected, it could result in a catastrophic failure and possible loss of life. The 2 most common of these inspection methods are Ultrasonic and Radiography (X-Ray) . Most people are familiar with these being utilized in the medical profession but have no idea how important they are in many industries to insure product safety.

My first job at URT was performing X-ray on military aircraft F-15 horizontal stabilizer panels. Over the years at URT I became certified in multiple NDT methods of inspection. The inspection lab not only had the reputation as the premier lab in the country, it also had the reputation as the lab providing the best quality of inspections.

There was not a busier inspection lab at the time. Many labs in the U.S. including the North Texas area were struggling to compete with URT. But after a few years at the company, I and other inspectors began to take notice of just how much product was moving through the lab. We were all doing our jobs, but began to notice that so much product was being moved that it was humanly impossible for the parts to have been inspected. As an example, some days our truck driver would travel to a local forging company and pickup 2-3 thousand forgings that required ultrasonic inspection. Actual required inspection time for three thousand forgings would be about 5 minutes each in some cases. So probably about 2 weeks for 1 inspector. But the forgings were being returned to the supplier the next day in many cases. So it became common knowledge at the company that the NDT supervisor who was also the Quality Manager was falsifying the inspections. We, the inspectors were doing our jobs, and rationalized that the forgings were non-critical parts, and we were not being ask to falsify inspections ourselves. Yes, this was bad, but it was the QA Manager signing the certifications for the inspections. The problem then gradually got worse.

The falsifying of parts moved from non-critical forgings to fracture critical aircraft components.

A fracture critical part is defined as a part that if it were to fail could cause a catastrophic failure and possible loss of life.

By now most of us inspectors are talking daily among ourselves about how bad the situation had become. How many parts are now having their inspections falsified? Thousands each week. More and more fracture critical. Then one day the Quality Manager and Owner calls for a company meeting. They gathered us all together to inform us that a F-15 Fighter Jet wing skin peeled in flight, and that URT was the inspection lab on record to have performed the NDT. No one was injured and the plane landed safely, but it could have been much worse. We inspectors were well aware of why the part failed. The NDT Supervisor had falsified the required ultrasonic inspection, and had been doing it for years. But at the meeting the Supervisor and Owner blamed us inspectors. But we all knew what really happened. The inspection had been falsified.

Despite all the audits from the airplane manufactures, and the military no one ever seemed to check what really mattered. We joked that they only come for the steak dinners. The F-15 event was the deciding factor that pushed me to become a whistleblower. Most of us believed that although it was the Quality Manager falsifying the inspections, that the company owner was also aware of the fraud taking place. A couple of the inspectors had meet with the owner and voiced their concern, but were never satisfied with his answers. This caused many inspectors to find other employment.

I had been discussing the fraud with my attorney for a couple of years. He always told me to let him know when I was ready to do something. I had worked at the company for 10 years by now, and felt I should try and stop the fraud before actually blowing the whistle. So one day I confronted the Quality Manager in the lobby. I voiced my concern that someone was going to die if he didn’t stop. During the very heated argument, he told me it was none of my business. Even the threat of calling the government did not seen to get my point across. Although he promised to start inspecting more, he never did.

In 1991 my wife and I talked about the issue and she knew it had been causing me great stress. We both agreed it was time to act. I scheduled a meeting with my attorney in Decatur, Texas. At this meeting he placed a phone call to the U.S. Attorney General’s Office in Fort Worth, Texas and requested protection for me under the U.S. Whistleblowers Act. Protection was granted.

For the next 3.5 years I worked with the U.S. Department of Justice to shut down Ultrasonic Research. Although there is not enough time here to go into all the details of the case, I must say it was very rewarding to have played the major role in shutting down this fraud machine. We shut down a company that was falsifying an estimated 200,000 parts per year. The damage caused to the aerospace industry was estimated to be in excess of $200 Million.

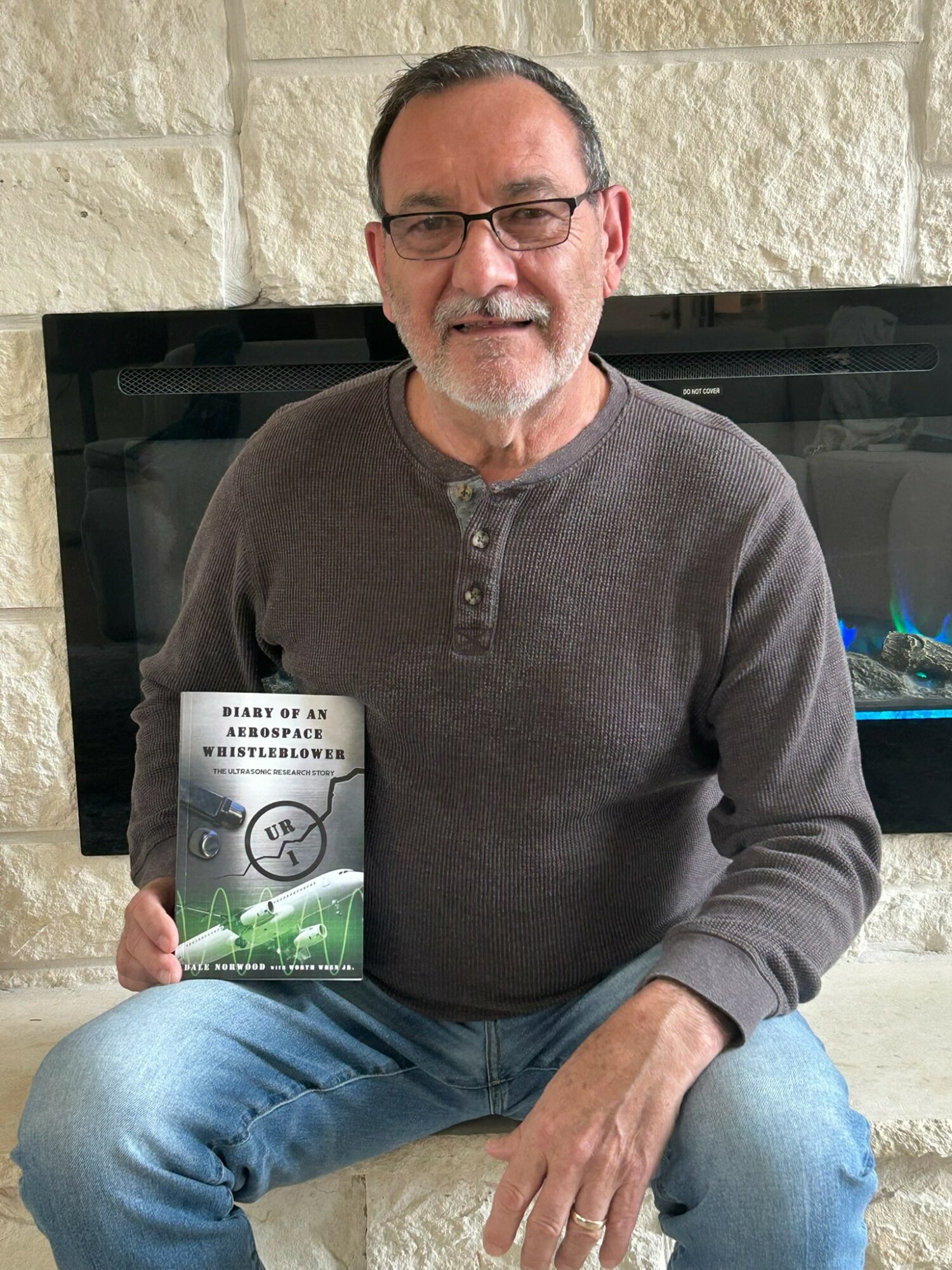

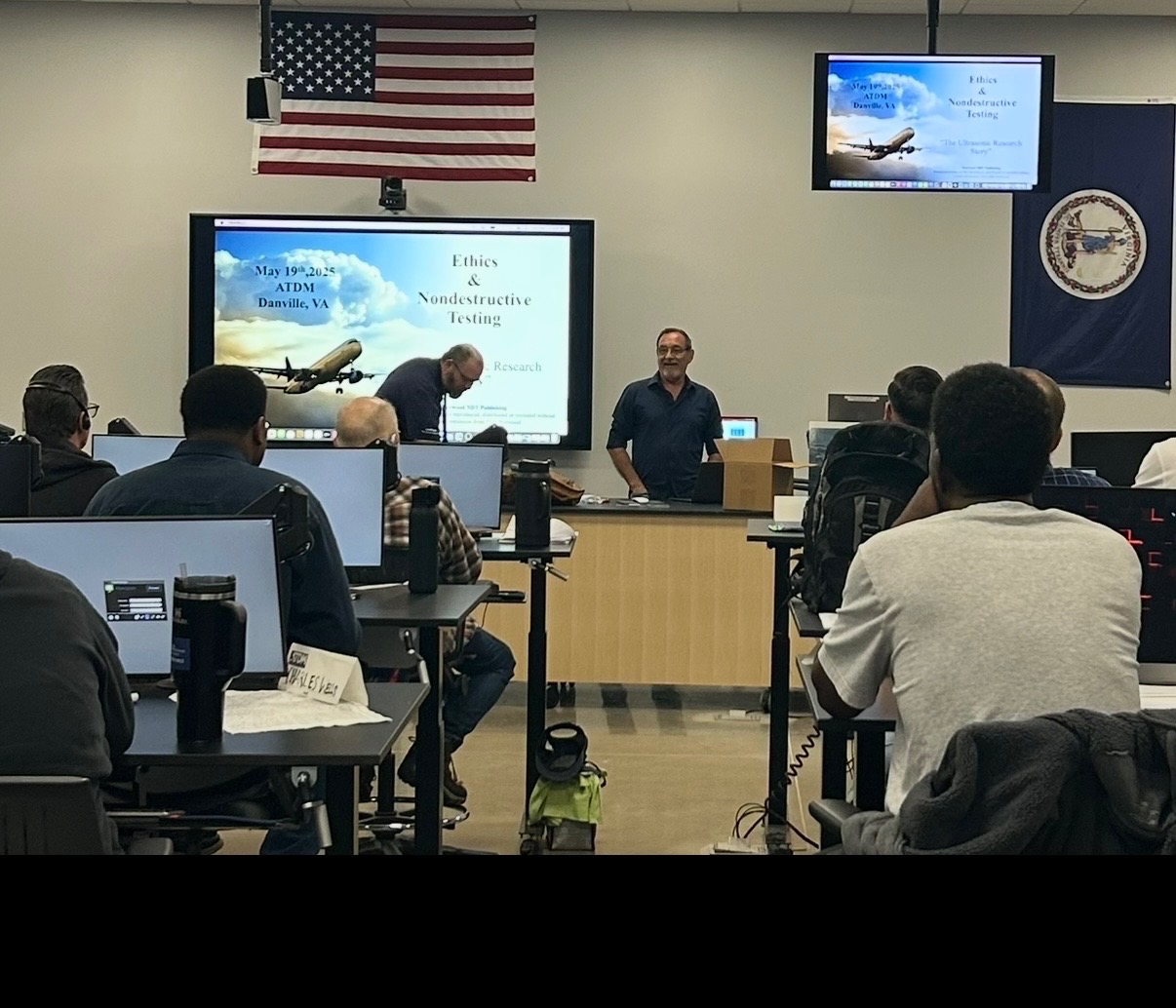

I now work as an NDT Consultant, and also speak on Ethics to various companies and colleges. I’m the past President of North Texas ASNT and Past Chairman of Tarrant County College Non-Destructive Training Program Advisory Committee.

What was it like working with the D.O.J.? Did I believe I was treated fairly? Were the guilty parties held accountable and punished? My attorney warned me I would never work in the NDT industry again if I went forward and blew the whistle? Was he correct? We feared threats on my life. Did it happen?

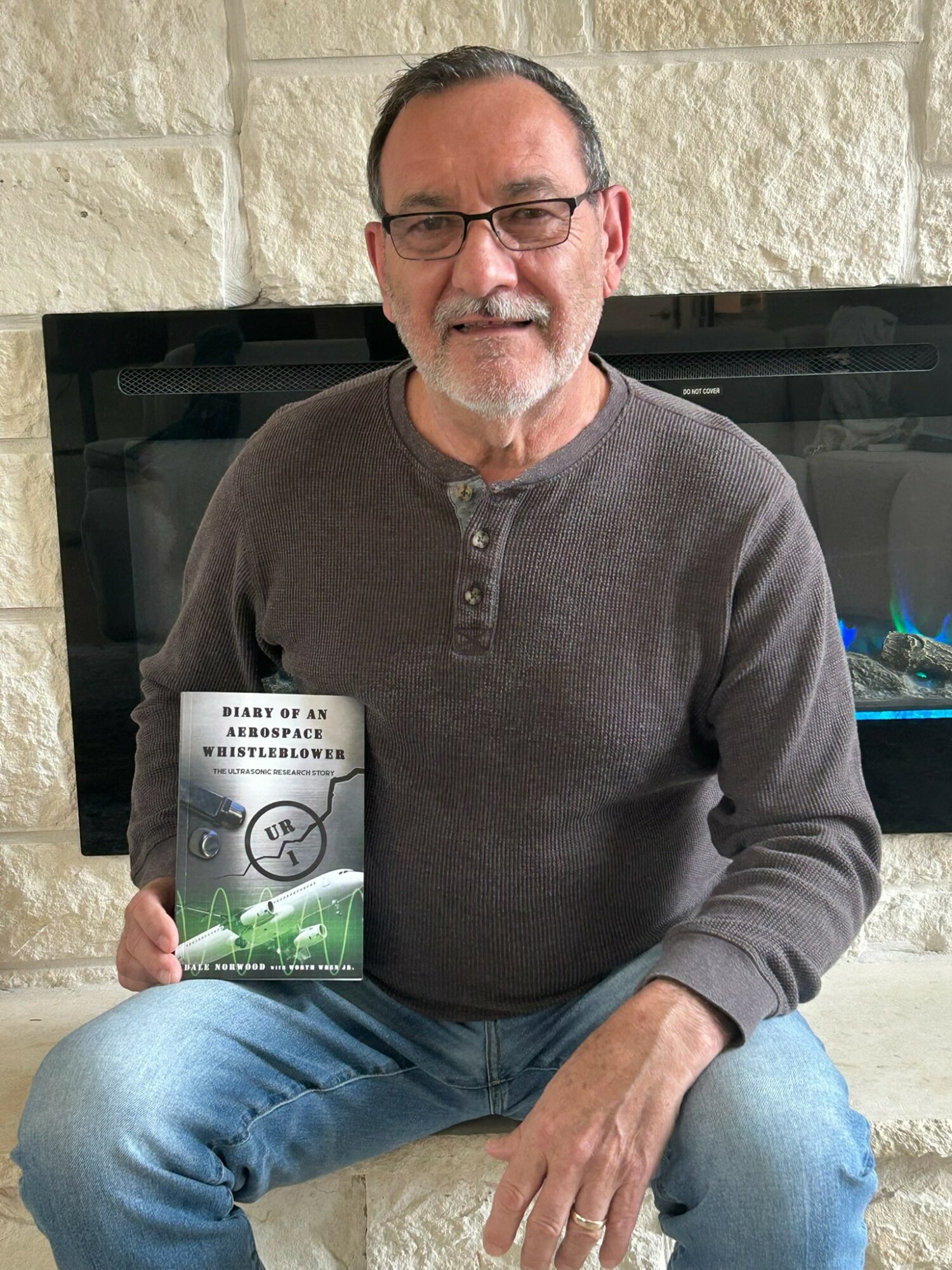

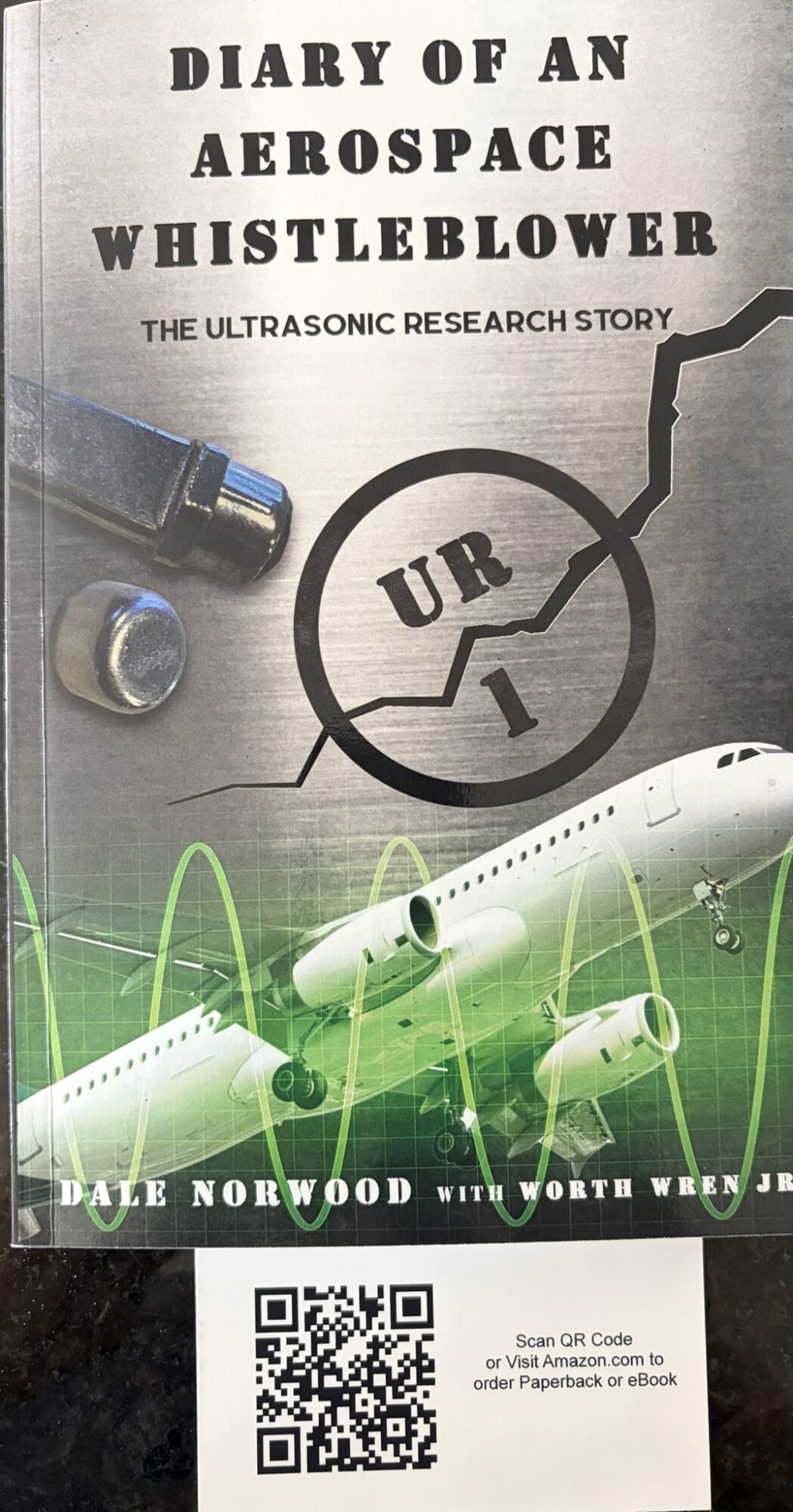

In 2022 I published a book documenting my experience as a Whistleblower. I cover the good and the bad.

“Diary of an Aerospace Whistleblower” Available through Amazon.

Would you say it’s been a smooth road, and if not what are some of the biggest challenges you’ve faced along the way?

I thought it would be a quick and easy process. It seems easy enough, simply turn in the company committing fraud, and the government will shut them down. It was not a smooth process. The very first challenge was convincing the D.O.J, the Defense Department and other government officials that what I was telling the truth. Many fought me along the way. Many of the Defense Department Reps had visited Ultrasonic Research many times, and had gotten to know the Owner and QA Manager very well. They had the same opinion of URT as most in the industry. URT was the best and could do no wrong. There were days I would call my attorney and ask “Why am I being treated like the guilty party” as the Whistleblower they would not have a case without me!

I struggled with the thought of possibly being responsible for putting individuals that had become my friends in prison.

As my wife would always tell me, “Dale they may be your friends, but they are also crooks” Many of my close friends who did no wrong would lose their job if the company was shut down. And on top of all of that, I had a family to take care of. A wife and very young twin daughters and I feared being able to support them if I was black listed in the NDT industry.

Alright, so let’s switch gears a bit and talk business. What should we know about your work?

I spent 45 years in the Non-Destructive Testing industry before retiring in 2021. There are multiple levels of certifications in NDT. The highest being Level 3. I was a Level 3 for Parker Aerospace for 20 years before my retirement. After retirement I formed Norwood NDT Consulting and I am loving it. I have multiple aerospace companies that I consult for. I certify NDT inspectors, write inspection procedures, perform Radiation Safety training and teach the required NDT Method Classes. I specialize in Digital Radiography and Fluorescent Penetrant Inspection. My classes are held on site at the company or at my NDT Training facility in Granbury, Texas.

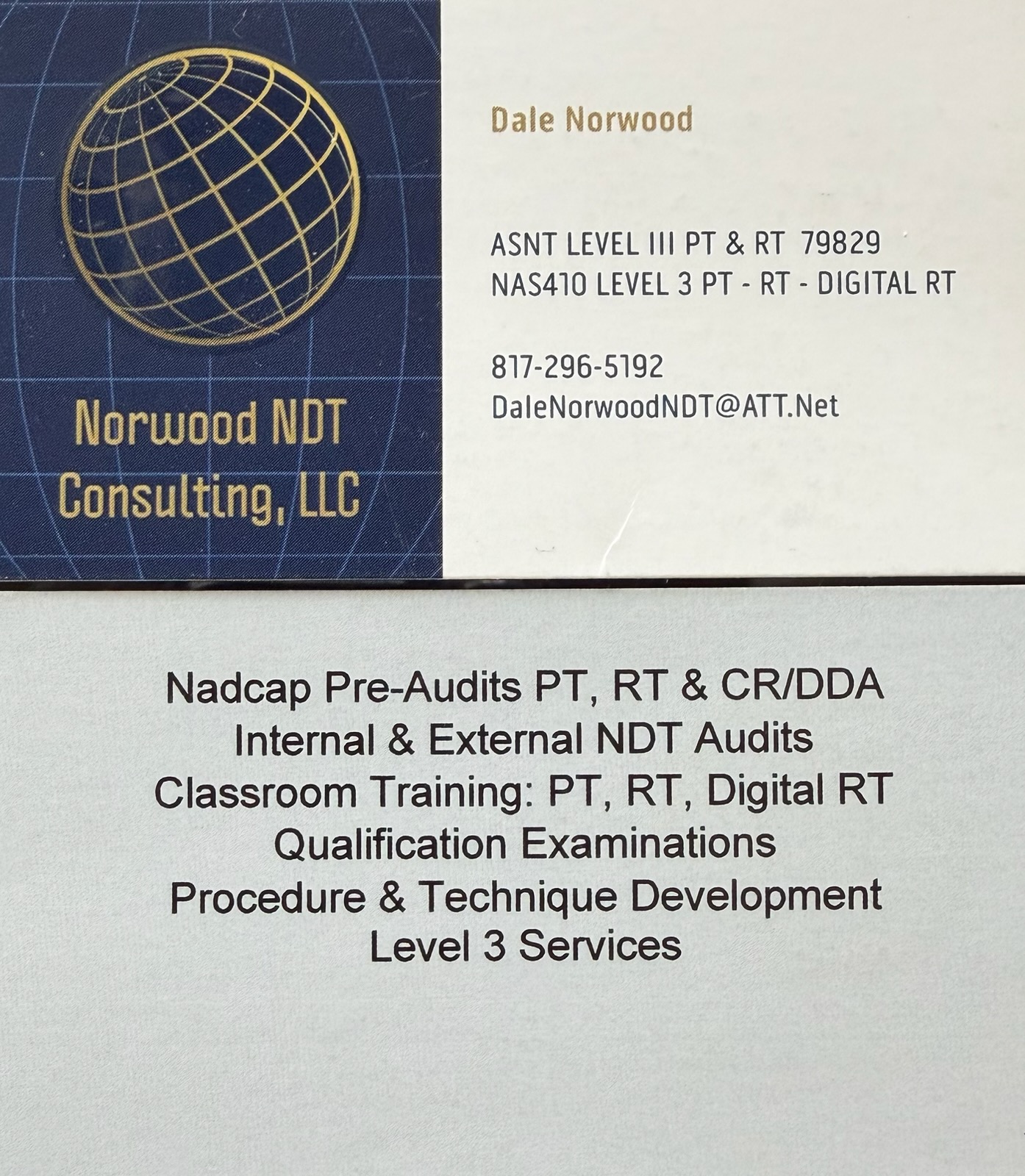

What sets me apart from others in the industry? I am known for speaking before various groups about Ethics in the Aerospace Industry. Since the release of my book in 2022 I get asked to speak multiple times a year at seminars, companies, and colleges. I try to get the point across to the groups I speak to that ethics is very important in our industry. You have a responsibility to do your job correctly without short cuts. The safety of many people depend on it.

I especially love speaking to young students in college NDT programs. Besides discussing my experiences, I also cover multiple other NDT fraud cases and the fines and or prison time the guilty inspectors received. I believe that it truly helps open the eyes of the students, and helps them realize just how important their future NDT job is.

A few of my past speaking engagements:

* NDTMA Conference: Golden Nugget, Las Vegas, NV

* ASNT North Alabama Section: Meridianville, AL

* Advanced Training in Defense Manufacturing: Danville, Virginia

* Quality Show South: Nashville, TN

* Dassault Falcon Jet – Alliance Airport, Ft. Worth, Texas

What are your plans for the future?

I plan to continue consulting, but plan to cut back over the next couple of years. I plan on spending more time with my wonderful 7 grandkids. I will still continue to speak when the opportunity arises.

Although I am planning on slowing down a bit, I’m in the home stretch of adapting my book “Diary of an Aerospace Whistleblower” into a screen play. Who knows, maybe I’ll have a new career in the future.

Contact Info:

- Website: https://NorwoodNDTConsulting.com

- Other: Diary of An Aerospace Whistleblower: amazon.com/dp/BOBMT22RXW

Image Credits

1st Photo : Dale Norwood & Book

2nd Photo: Norwood NDT Business Card

3rd & 4th Photo: Speaking at ATDM, Danville, Virginia

5th Photo: Book & Order Info.